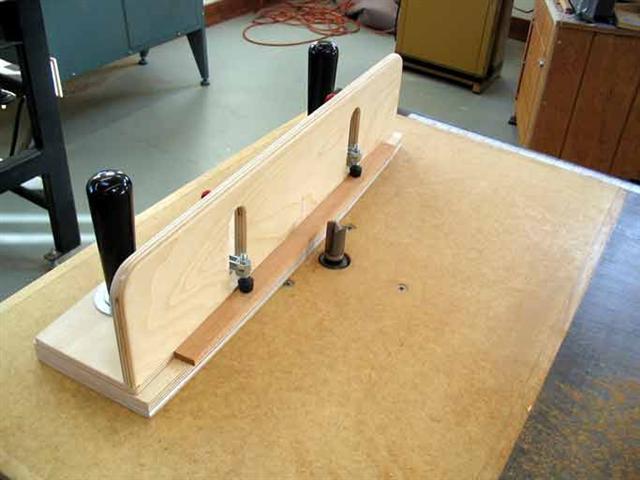

I'm making a brace profiling jig, similar to the above. Has anyone made one like this?

Someone used to sell plans for this on ebay. I made a couple versions and prototypes.

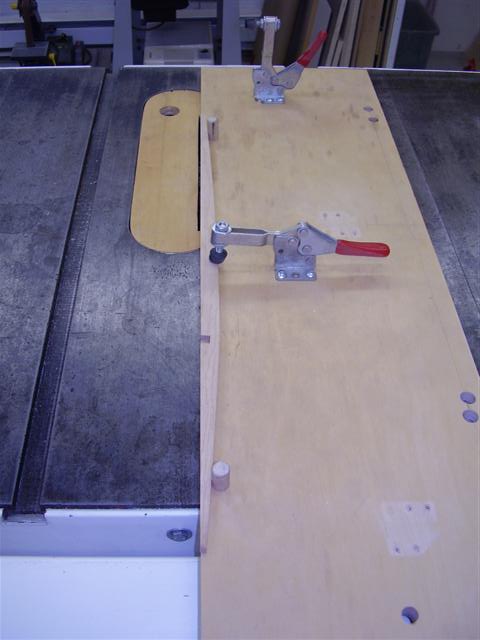

I like the safety guard, but you have to bend over it to see what you're doing. (Adding more risk)

Improvements I plan to make are:

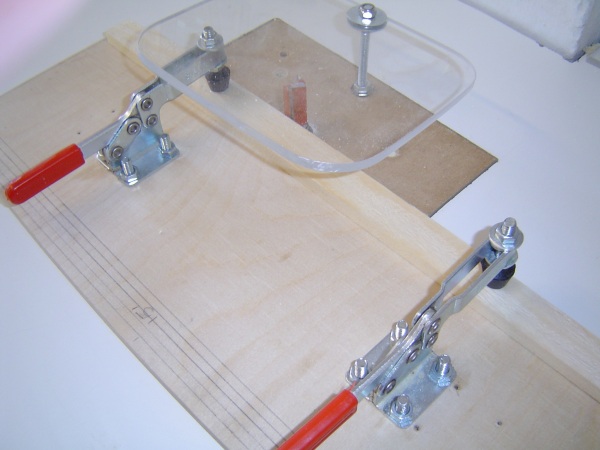

replace safety guard with plexiglass

add a third toggle clamp (to reduce vibrations and blowout on the ends)

Any input? Any pictures? Any plans?

) only difference is the possible danger factor. No blowouts, and if you use that great saw blade of yours, I bet your good to glue after the cut. (BG)

) only difference is the possible danger factor. No blowouts, and if you use that great saw blade of yours, I bet your good to glue after the cut. (BG)

. I love jigs an doodads but sometimes the direct simple approach makes sense.

. I love jigs an doodads but sometimes the direct simple approach makes sense.